Mayorga Coffee produces 30 different coffee roasts and supports local organic farming methods by working directly with small, family-owned coffee growers in Mexico, Bolivia, Colombia, Costa Rica, El Salvador, Guatemala, Honduras, Nicaragua and Peru.

“We produce a product that is sustainable, not only for the planet, but for the people growing it as well,” said Erin Dall, President and COO. Mayorga sees its direct purchases, without complex supply chains, as an important factor to reducing poverty in Latin America. Free Roller Driven Spiral Conveyor

Founded in 1997 and headquartered in Rockville, Maryland, the company until recently operated a 3900 m2 roasting and packaging facility in Miami, Florida to produce its premier product, Café Cubano Roast organic coffee, in vacuum-sealed brick packs.

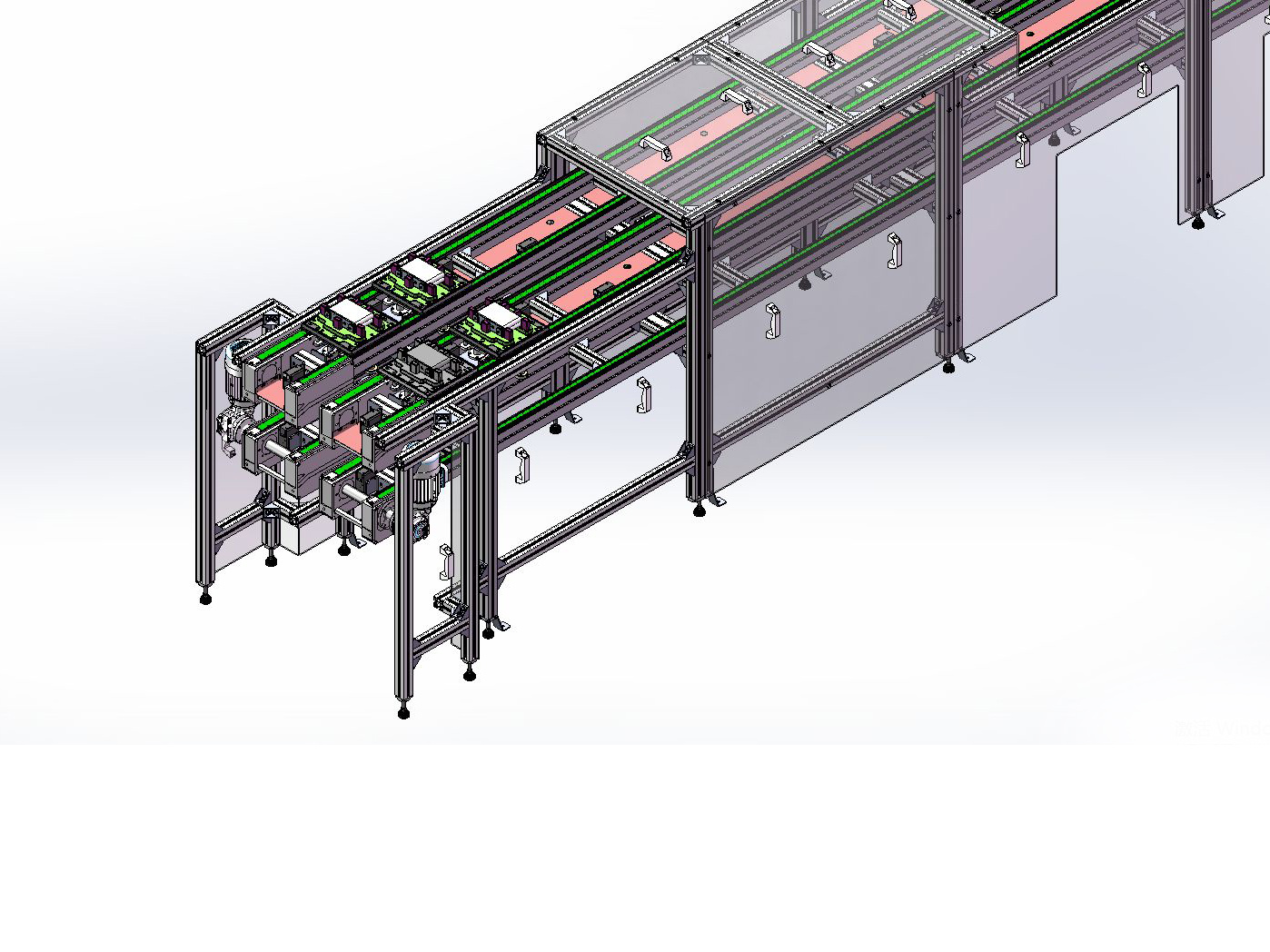

To transfer the coffee beans from roaster to grinder to packaging line, the company installed a bulk handling system comprising two bulk bag dischargers, three flexible screw conveyors and a bulk bag filler, all from Flexicon Corporation.

The flexible screw conveyor at left transfers roasted coffee beans from the bulk bag discharger to the grinder, while the conveyor at right moves ground coffee to the bulk bag filler.

Roasted coffee beans are discharged from the roaster into open-top bulk bags and delivered to a BFF BULK-OUT bulk bag discharger. A forklift then positions a bag-lifting frame immediately above the bag, allowing an operator to slide the bag’s four lifting straps into Z-CLIP strap holders, and the forklift to lift the frame ― with suspended bag ― into receiving cups atop the discharger’s frame posts.

At floor level, an operator attaches bulk bag straps to Z-Clip strap holders of a bag lifting frame held in position by a forklift.

The discharger houses a bulk bag spout interface chute with an integral access door. With the bulk bag in position, the operator opens this door to gain access to the bulk bag spout tie. Once the spout has been untied, the access door is closed while roasted beans are discharged from the bulk bag.

The beans flow from the bulk bag into a 226 L floor hopper, which charges a 4.57 m model 1350 flexible screw conveyor inclined at 45° to feed the grinder. The 90 mm diameter enclosed conveyor tube is designed to prevent product and plant contamination. The inner screw is the only moving part contacting material and is driven by an electric motor positioned beyond the point at which coffee beans exit the conveyor, preventing material contact with seals.

From the grinder, ground coffee gravity discharges into a 113 L floor hopper that charges a second 4.6 m long, 90 mm diameter flexible screw conveyor, this one equipped with a spiral designed to efficiently propel the fine-ground material to a Flexicon model BFB bulk bag filler.

Flexible screw conveyor transfers ground coffee from the grinder through downspouting to the bulk bag filler.

A palletised open-top bulk bag is placed inside the filler frame, which can be adjusted to accommodate bulk bags ranging from 914 to 1828 mm high. Strap hooks, mounted on each of the four corners of the fill head, hold the bag open and stabilise it during filling.

Filled bulk bags are forklifted into a second discharger which unloads coffee into a 226 L floor hopper charging a 4.7 m long, 51 mm diameter flexible screw conveyor to feed the packaging line.

Low- and high-level sensors on the packaging machine hopper signal the system’s PLC when to start and stop the conveyor.

Dall said the bulk handling system improves productivity and plant cleanliness. “Flexicon provided a solution that fits within our space limitations, allows immediate packaging and provides for future production expansion.”

Do you want to produce safe traceable food products while also increasing yield? Here are seven...

With global demand for kiwifruit increasing, packhouses are left with the objectives of...

AI enables food manufacturers to improve their operations by improving quality control and food...

Elevating Food & Beverage Safety Standards With The FABS Series

Baby Formula Production Equipment being sold by Slattery Auctions

Siemens' partner APS to manufacture and adapt critical technology for Australia's energy transition in Adelaide

All-in-one food and beverage batching solutions

We are removing plastic labels

Stationary barcode readers for detection of 1D codes/barcodes in production and logistics

Leuze DRT25C — dynamic reference diffuse sensor

Partnership to provide AI-generated patient summaries in real time

Fake nurse jailed in Ahpra prosecution

New pharmacy recognition program launched

AIHW releases 10-year dementia data improvement plan

NASA's first ever asteroid sample has landed on Earth

Air pollution impacts bees' ability to find flowers

Disrupted link between memory and appetite explains obesity

Breakthrough drug targets life-threatening 'bad cholesterol'

Small-scale bioreactor helps create cultivated meat

Redflow to provide microgrid system for US Department of Defense

JBS Australia commences construction of a bioenergy system in Scone

Ampcontrol partners with University of Newcastle

Fortescue announces it will drop voluntary offsets

Whyalla takes last coal shipment in move towards green steel

Westwick-Farrow Media Locked Bag 2226 North Ryde BC NSW 1670 ABN: 22 152 305 336 www.wfmedia.com.au Email Us

Our food industry media channels - What’s New in Food Technology & Manufacturing magazine and the Food Processing website - provide busy food manufacturing, packaging and design professionals with an easy-to-use, readily available source of information that is crucial to gaining valuable industry insight. Members have access to thousands of informative items across a range of media channels.

Pallet Conveyor Transfer Membership is FREE to qualified industry professionals across Australia.