Carl Knight – managing director of process steam and heat transfer specialist Fulton – looks at the advantages of electric steam boilers versus their traditional fuel-fired counterparts.

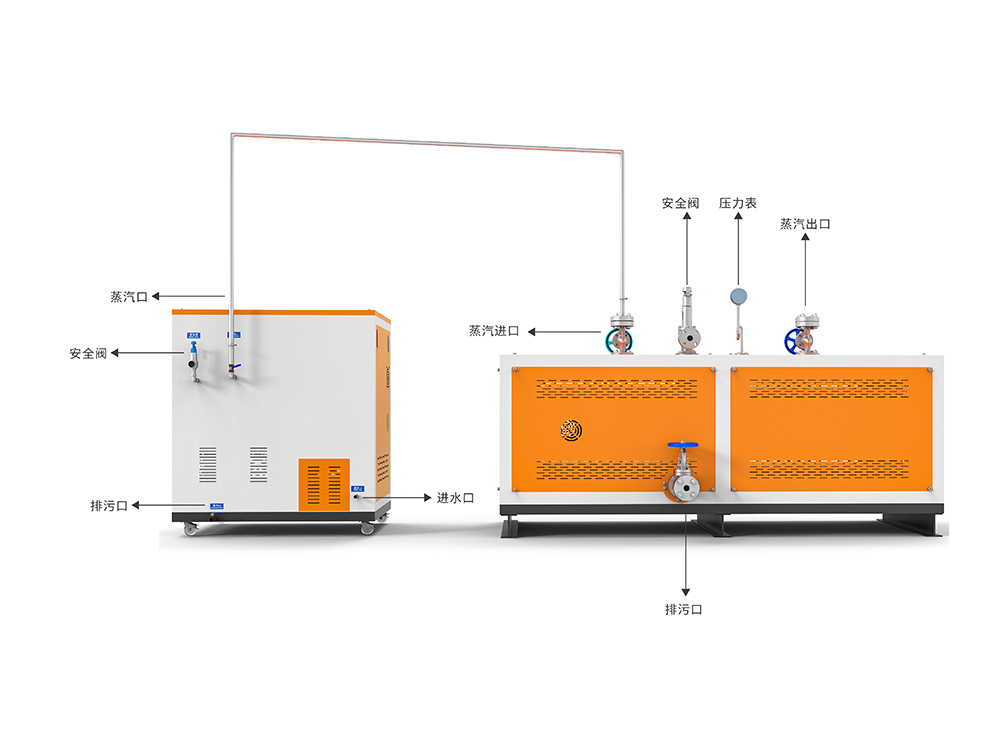

Electric steam boilers work in a very similar way to fuel-fired boilers except in the way that the water is heated. Hot Steam Generator

The process of creating steam with an electric boiler is a relatively straightforward one. Electricity is passed through a heating element that acts as a resistor to create heat through resistance. Water from the feedtank is then pumped into the pressure vessel, heating the water enough to boil and become saturated steam at (depending upon the pressure setting controller) typically between 6 and 10 Barg, at which point the saturated steam is available to the process.

Some believe that electric steam boilers are superior to fuel-fired steam boilers in a few ways. They believe that using electric boilers may be less expensive than using a fuel-fired boiler in the long term, whilst also possibly being more environmentally friendly.

Using Fulton’s portfolio of electric steam boilers as an example, less ancillary equipment is required than a traditional steam boiler, therefore helping to reduce the installation costs that come with a fuel-fired boiler. Electric boilers also generally have a smaller footprint and can therefore fit into smaller areas thanks to the way they are constructed and the lack of ancillaries that a fuel-fired boiler needs to operate.

Electric boilers are sometimes overlooked as a potential solution to steam generation due in part to the higher cost of electricity versus the cost of traditional fuels. To help meet its climate change and air quality targets, in the 2020 budget the government announced that it would remove the entitlement to use red diesel from most sectors, including for use in industrial boilers, from April 2022. The tax changes will ensure that most users of red diesel will use fuel taxed at the standard rate for diesel from April 2022. As a result, many companies are now turning to more sustainable methods of generating electricity, including solar or wind generation. These schemes offset, or at least partially offset, the higher fuel costs.

Traditional fuel-fired steam boilers generally require multiple elements to operate successfully. In contrast, electric boilers are relatively simple devices. Additionally, because electric steam boilers do not use complicated forms of heat exchange, they do not contain many of the potential hazards that are commonly present in a fuel-fired boiler and will simply trip out if elements are exposed due to low water conditions that can arise in the operation of steam boilers.

Electric boilers are also generally easier to maintain because they have no heat transfer tubes, nor require burner maintenance or statutory non-destructive testing (NDT), all of which fuel-fired boilers often require. Electric boilers also have smaller carbon footprints than their counterparts and, again thanks to their small footprints, can often be used for point-of-use steam requirements, making them a good choice for many smaller operations needing steam.

Another benefit that should be considered is sustainability, thanks to their low maintenance requirements; and marketability owing to their green attributes, in the same manner as electric vehicles are seen as “green” versus petrol or diesel counterparts.

Electric steam boilers are also more efficient than fuel-fired boilers because they require less energy to be put into them for operation at capacity. This is because there is little energy lost when the transfer of heat from the heating element to the water occurs, unlike traditional fuel-fired boilers where there is a substantial amount of energy loss from the air flow required to supply oxygen to the flame.

Additionally, because electric steam boilers can be fitted, in some cases, with up to 15 electrical elements (dependent on model), they have a high turndown (up to 15:1 in the case of Fulton’s electric steam boiler range), so are able to modulate efficiently to varying steam loads.

Electric boilers are, as already stated, more efficient, but for large generating capacities are frequently not practical to install due to large supply cables and infrastructure requirements. However, the actual maintenance costs can be up to 50% less than those of fuel-fired steam boilers. Generally, the only major parts that are periodically changed are the electric elements themselves, yet these are often replaced quickly and cost effectively. This balances lower life cycle costs against the high maintenance requirements of fuel-fired boilers, including refractory repairs, 5-year NDT requirements, burner maintenance, flue maintenance and the requirement for highly-skilled and often highlypaid plant operatives.

For additional information please visit www.fulton.co.uk

With manufacturing facilities in the United States, Great Britain and China, Fulton is a global manufacturer of steam, hydronic and thermal fluid heat transfer systems. Backed by over 60 years of research, innovation and experience, Fulton is building on a tradition of success and is focused on improving life through heat transfer solutions.

https://www.linkedin.com/company/fulton-boiler-works-gb-limited/

Clive Jones, Managing Director of thermal fluid specialist Global Heat Transfer, explains how proactive thermal fluid management is the key to safe and efficient operations.

Predictive maintenance and RCM (reliability-centred maintenance) programmes at manufacturing facilities regularly use thermal imaging cameras for inspecting a countless number of mechanical components. FLIR tells PWE how to get started.

With energy conservation an increasingly hot topic within the process heating industry, stakeholders are now looking towards innovative methods to reduce energy consumption. Rob Brown, technical manager for Industrial Boiler Plants at Bosch Commercial and Industrial Heating, explains how a combination of technologies can be used to accompany a steam boiler to maximise energy efficiency.

SPIRAX SARCO reports it has launched the industry’s most comprehensive range of desuperheaters for precise control and efficient heat transfer when cooling superheated steam. Featuring a high turndown of up to 50:1, the desuperheaters are said to be suitable for a wide range of applications and increase process efficiency by allowing waste and residual heat to be recovered and recycled. They can also protect process plant from damage caused by overheating.

Brent Hall, technical manager at ICS Cool Energy, offers nine top tips for using glycol in chillers and chilled water systems.

To view a digital copy of the latest issue of Plant & Works Engineering, click here . View the past issue archive here . To subscribe to the journal please click here .

"How is your manufacturing business preparing for a net Zero target?"

Click here to see all 12 events

Residential Steam Generator Click here to let us know about an event!