By Alexandra Foran, NSRDEC Public AffairsSeptember 19, 2013

NATICK, Mass. (Sept. 17, 2013) -- One of life's greatest necessities, water, is a key ingredient for the new gentle motion retort used by the Combat Feeding Directorate at the U.S. Army Natick Soldier Research, Development and Engineering Center to develop Meals, Ready-to-Eat and Tray Pack products. Pilot Retort

This simple molecule is heated to 240 degrees Fahrenheit in order to cook and sterilize foods using one of three different thermal processing methods.

After the successful "retort" process items do not require refrigeration because they have achieved commercial sterilization, the removal of certain pathogenic organisms.

The retort vessel installed at the NSRDEC in January 2013 can process 195 eight-ounce Meal, Ready-to-Eat, or MRE, pouches, or 20 six-pound polymeric Tray Packs at a time using water immersion, saturated steam, water spray or water spray with gentle motion.

During the water immersion mode water fills the processing vessel, which holds up to 185 gallons, and completely submerges the product. This water is then heated to 240 degrees Fahrenheit and held for a prescribed period of time. In the steam process saturated steam is injected into the vessel.

The water spray mode utilizes three steam "sparges" located at the bottom of the processing vessel to shower the packaged food product with hot water at high pressure. Through each of these methods heat penetrates the sealed pouches or trays, eventually reaching the point of product sterilization.

Products typically cook in the processing vessel using either method for approximately 45 to 85 minutes. A cool down phase also occurs prior to removal of the product from the vessel.

In the newest, most novel method, water spray with gentle motion, showering the product with hot water is followed by introduction of the motion factor, where the vessel rocks the product back and forth at up to 50 strokes per minute.

"Using the water spray with gentle motion method, we're shortening the total processing time," said Frank DiLeo, physical scientist on the Combat Rations Team. "If you reduce processing time, you're saving money and electricity. Also, the spray water is recycled, so there's not a lot of waste involved in this particular mode."

Different products do require different processing times in the retort because of the quantity and density of the food products that go into the packages.

"Rice is a very dense product compared to a beef stew, which has a lot of free liquid," said DiLeo. "Free liquid is important because it helps with heat transfer. Heat penetration will inactivate and destroy the pathogens. Minimizing the processing time improves the quality of the product, most notably the flavor and appearance."

Although cook time is mandated by the Food and Drug Administration to ensure the inactivation of pathogenic organisms and achievement of commercial stability, the gentle motion retort can reduce the total processing time by up to 40 percent because the heating and cooling times are shorter than with most other processes.

This laboratory-sized retort vessel also streamlines the new product development and testing process, as similar gentle motion retorts are now used by the commercial vendors producing MRE pouches and Tray Packs for the military.

"Now, at the bench level, we can design products and process them the same as our vendors would," said DiLeo. "You're reducing the barriers to scale-up because you have a more industry-compatible system."

Transitioning shelf-stable food products from the research and development level to vendors and ultimately to warfighters has been made easier at Natick.

Researchers said the new retort vessel helps to ensure new food products developed by the Combat Feeding Directorate are not only safe to consume, but also thermally processed in a much more efficient manner. Warfighters may soon see more visually appealing, nutritious and delicious shelf-stable ready-to-eat foods, they said.

NSRDEC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Natick Soldier Research, Development and Engineering Center

U.S. Army Materiel Command

Army.mil: Science and Technology News

U.S. Army Research, Development and Engineering Command

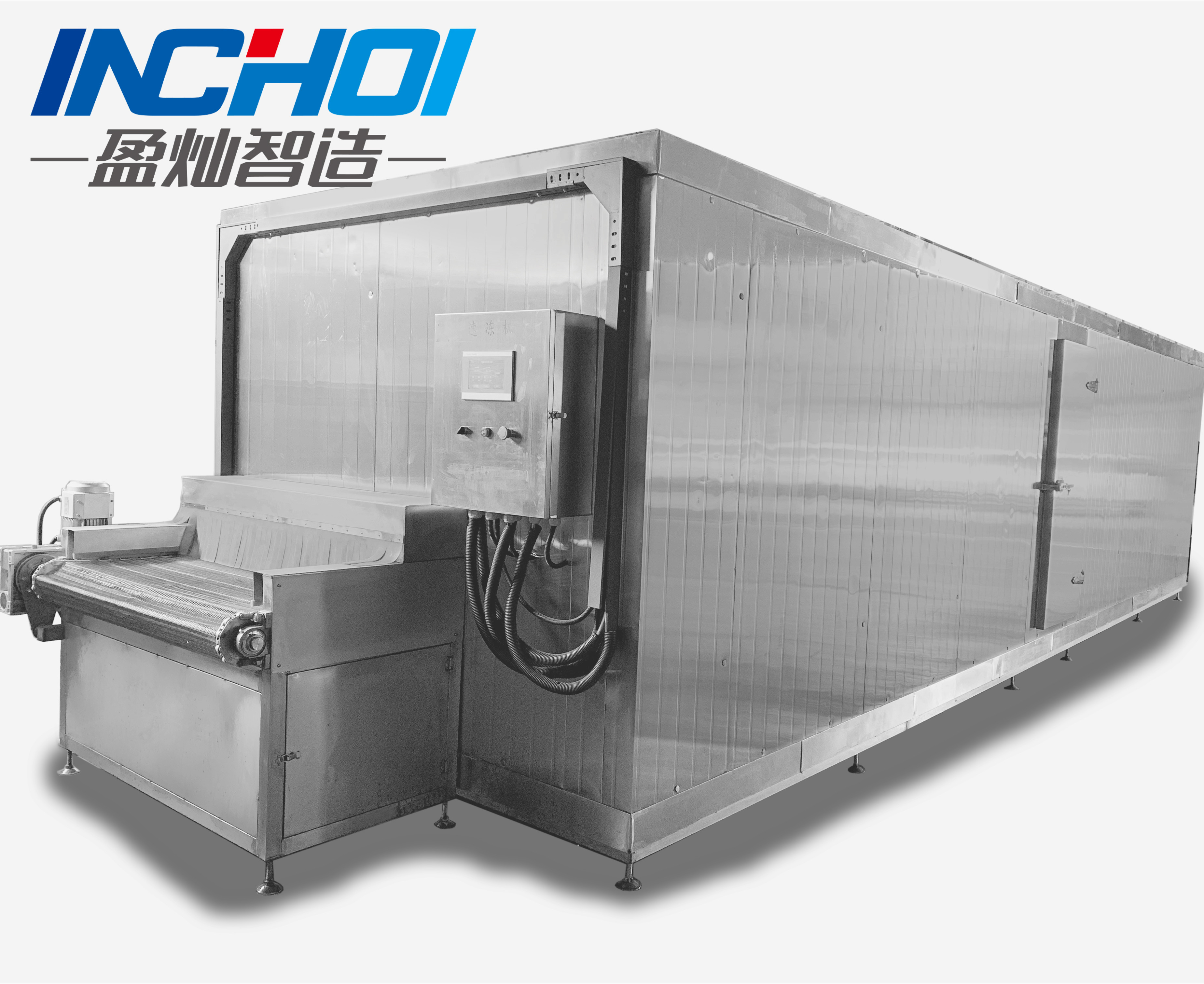

Autoclave Sterilization Machine NSRDEC's Frank DiLeo prepares to use a new retort food processing system